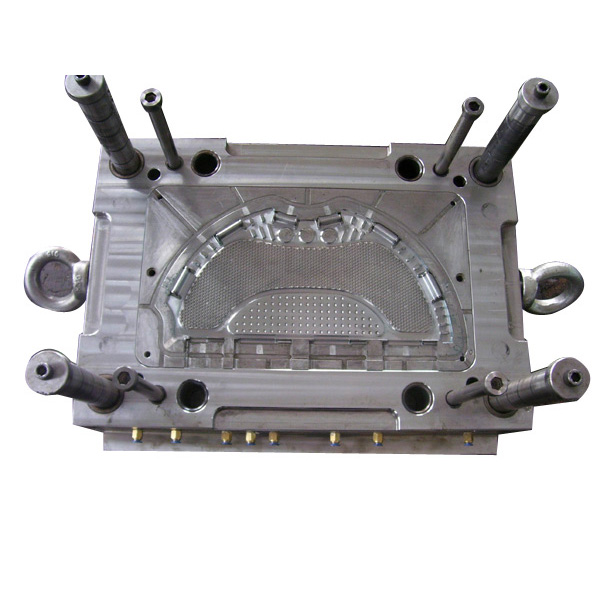

Plastic Mold

Plastic Mold

Plastic injection moulding is a process of melting plastic pellets and injecting it into a mould or cavity to form a shape. Once the shape is formed, the material is cooled, ejected from the machine and – voilà – a finished, functional, esthetically pleasing injection moulded product or part is ready

The advantage of plastic mold making:

1. Repeatability: the mold can be produced in the thousand millions

2. Accuracy: tight tolerance consistently

3. Functionality: can have complex shapes that cannot achieved by other materials and process

4. Surface finish: a wide spectrum of surface finishes can be achieved

Product Tag: