Precision Engineered: Advanced Aluminium Die Casting Solutions for Optimal Thermal Management

Innovations in Custom Heatsink Design and Manufacturing Drive Performance Across Industries

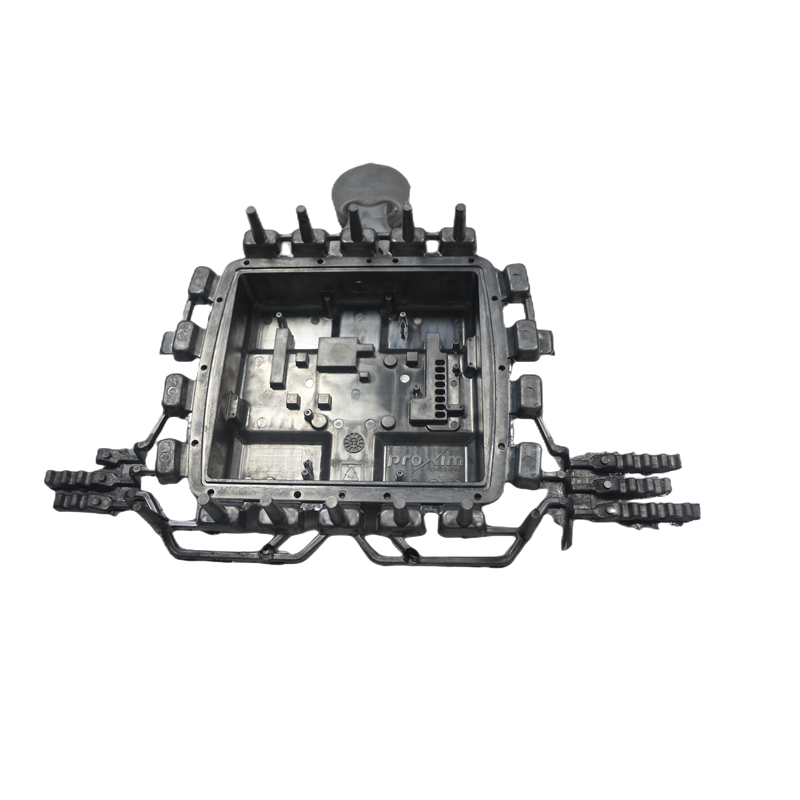

In today’s high-performance engineering landscape, effective thermal management is paramount. At the forefront of this crucial sector, our manufacturing expertise delivers precision Aluminium die casting solutions specifically engineered for superior Heat Radiation. We specialize in producing high-performance Heatsink components and complex Aluminum casting assemblies that meet the rigorous demands of global industries.

Unmatched Technical Capabilities in Die Casting & Fabrication

Our core competency lies in advanced high-pressure Aluminium die casting, utilizing premium alloys such as ADC12, A380, and LM6. This process is the foundation for creating robust, lightweight, and thermally efficient components. Each project begins with the engineering of a Custom Heatsink or housing, designed to maximize surface area and cooling efficiency. The journey from raw material to finished product involves a seamless integrated process: precision die casting, meticulous deburring, accurate drilling and tapping, and specialized CNC machining to achieve tight tolerances of +/-0.05mm. We support all standard DRW formats, including PDF, DWG, IGS, and STEP, ensuring perfect design fidelity.

Meeting Diverse Industrial Demands with Precision

The exceptional Heat Radiation properties of our Aluminum casting products make them indispensable across critical sectors. Our Aluminium die casting services cater to the stringent requirements of automotive systems, marine electronics, medical devices, aerospace components, and durable home appliances. Every Heatsink and cast part is developed to manage thermal loads effectively, ensuring reliability and longevity in end-use applications. With a monthly capacity of 10,000 pieces and an MOQ of 1,000 pcs, we balance large-scale production runs with dedicated project-based manufacturing.

Commitment to Quality and Comprehensive Service

Quality assurance is embedded in our production DNA. Our QC system mandates a 100% inspection before shipment, verifying dimensional accuracy, surface roughness down to Ra3.2, and overall integrity. We enhance component durability and performance with a variety of surface treatments, including anodizing, powder coating, and oil painting. Our dedicated packaging ensures all products, from a single Custom Heatsink prototype to large batch orders, arrive in perfect condition, with expedited sample delivery available.

Operating a full suite of modern equipment—from 280T to 3000T high-pressure die casting machines and multi-axis CNC centers—we guarantee consistency and excellence. We offer flexible payment terms and are committed to providing tailored thermal solutions, where optimal Heat Radiation is achieved through intelligent design and precision Aluminium die casting. Contact us to discuss your project requirements and partner with a leader in advanced aluminum thermal component manufacturing.

Contact Information

Brand: SMI (Origin: China)

Email:sales@smicasting.com

Phone/WhatsApp:+86-755-29742490

Partner with us for turnkey aluminum base plate production—combining rapid die casting, precision machining, and premium finishes to bring your designs to life.