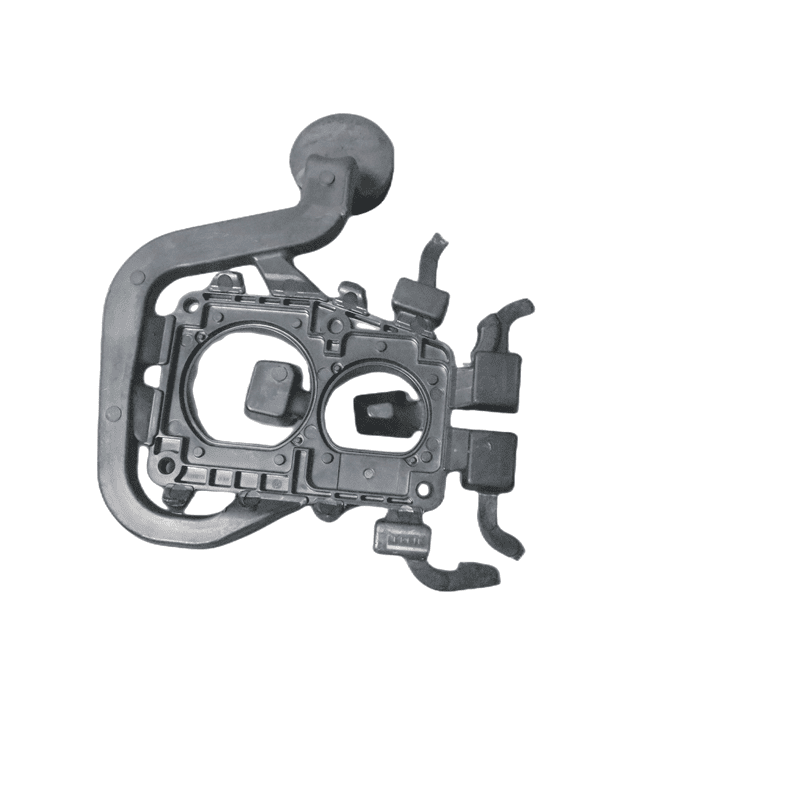

Custom Aluminum Base Plates & Metal Castings

We offer high-pressure die-cast aluminum base plates—ideal as structural or decorative metal bases for lighting fixtures, machinery mounts, and architectural panels. Engineered for precision, durability, and attractive surface finishes, our bases combine the efficiency of die casting with optional CNC machining to meet tight tolerances and complex geometries.

Key Features

• High-Pressure Die Casting

– Cold-chamber machines (280–1,500 ton) deliver consistent wall thickness, minimal porosity, and near-net-shape accuracy.

• Premium Aluminum Alloys

– ADC12, A380 and other industry-standard alloys for optimal strength, corrosion resistance, and castability.

• Post-Process Versatility

– Secondary CNC milling, drilling, and tapping on 3- and 4-axis centers to achieve critical dimensions (tolerance to ±0.05 mm).

• Surface Treatment Options

– Anodizing (clear or color), bead blasting, powder coating, silk screening, and chemical passivation for functional and aesthetic requirements.

• Fine Surface Finish

– Achievable Ra 1.0–3.2 µm depending on mold polish and post-treatment.

Technical Specifications

Parameter | Specification

Material | ADC12, A380 (other alloys on request)

Process | Cold-chamber die casting + optional CNC machining

Machine Tonnage | 280 – 1,500 ton press capacity

Surface Roughness | Ra 1.0–3.2 µm

Secondary Machining | 3-/4-axis CNC centers

CAD Formats | IGS, STP, X_T

Design Software | Pro/E, SolidWorks, UG, 3D Max

MOQ | 1,000 pcs

Lead Time | 25 working days (from mold approval)

Production Capacity & Delivery

• Monthly Output: up to 5,000 pcs

• Delivery Time: 25 working days after design sign-off and deposit

• Packaging: Sturdy carton boxes or wooden crates (as required)

Value-Added Services

• DFM Consultation & Moldflow Analysis

• Tooling & Prototype Mold Builds

• In-House Tool & Mold Maintenance

• Quality Inspection: First-article reports, CMM measurement, and visual checks

Applications

• Lighting Bases & Fixtures

• Electronic Enclosures & Heat Sinks

• Machinery Mounting Plates

• Architectural Panels & Signage

• Decorative Hardware Components

Ordering & Payment

• Payment Terms: T/T (30% deposit, 70% before shipment)

• Sample Availability: Prototypes via rapid tooling (add 7–10 days)

Contact Information

Brand: SMI (Origin: China)

Email:sales@smicasting.com

Phone/WhatsApp:+86-755-29742490

Partner with us for turnkey aluminum base plate production—combining rapid die casting, precision machining, and premium finishes to bring your designs to life.