Precision Plastic Mold & CNC Manufacturing Solutions for Industrial Applications

Precision Plastic Mold & CNC Manufacturing Solutions for Industrial Applications

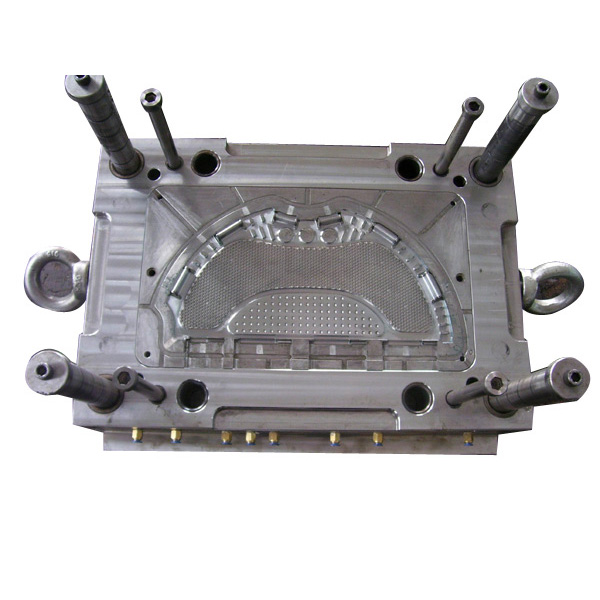

Plastic injection moulding is a high-efficiency process where melted polymer is injected into a Plastic Mold to create durable, dimensionally stable parts. At [Your Company], we combine this technology with CNC Machining services to deliver end-to-end manufacturing solutions for aerospace, medical, and automotive industries.

Why Choose Plastic Mold Manufacturing?

Repeatability – Produce millions of identical parts with <0.01mm variance

Accuracy – Achieve ±0.005" tolerances using CNC Machining-optimized molds

Complex Geometry – Create internal channels, thin walls, and organic shapes impossible with traditional methods

Surface Finish Options – From mirror polish to textured finishes (VDI 3400 standard)

Technical Insight: Our Plastic Mold process uses hardened tool steel (H13/NAK80) with conformal cooling channels to reduce cycle times by 30%.

Integrated CNC Services for Complete Workflow

1. CNC Prototype Development

• Rapidly test designs with aluminum or P20 steel molds

• Combine 3D printing and CNC Turning/Milling for hybrid prototypes

• Typical lead time: 5-7 days for functional validation

2. CNC Machining for Mold Production

| Process | Capability | Tolerance |

|---|---|---|

| CNC Milling | 5-axis machining for complex cavities | ±0.002" |

| CNC Turning | Precision cores and ejector pins | ±0.0005" |

Case Study: A medical device client reduced prototyping costs by 60% using our CNC Prototype service before full-scale Plastic Mold production.

3. High-Volume Production

• 80-300 ton injection molding presses

• Overmolding and insert molding capabilities

• Automated quality inspection with CMM

Industry-Specific Applications

Automotive:

• CNC Milled molds for lightweight PP components

• CNC Turned metal inserts for hybrid plastic/metal parts

Medical:

• USP Class VI-compliant Plastic Molds

• Micro-molding with <0.1g shot weights

Case Example: A drone manufacturer used our CNC Machining services to create aluminum compression molds for UAV housings, cutting tooling costs by 45%.

Why Partner With Us?

DFM Analysis: Optimize designs for Plastic Mold manufacturability

Material Expertise: From ABS to PEEK and liquid silicone rubber

Full Documentation: Mold flow analysis, PPAP, and IMDS reports

Request a Quote: Submit your CAD file to explore CNC Prototype or full-production Plastic Mold solutions today.